Felixstowe Area ďNĒ Gauge Group

MARCH 2021 NEWSLETTER

MEMBERíS ROUNDUP

Trevor - Clubroom access and events update

Looking at the governmentsí announcement of the possible lifting of restrictions we have deduced the following;

The earliest groups of people (max 6) can meet indoors is 17th May. At this time the rules around distance and masks will remain in force. If the change is confirmed, we can open the clubroom using the booking system used last year.

The maximum number we will allow in the clubroom is however 5, due to the size of the room.

The government have indicated that restrictions on indoor numbers might be entirely lifted on 21st June. However, the rules on distance / masks are to be reviewed at this time and not guaranteed to be lifted.

If the restrictions on numbers, distance & masks are all lifted at the same time then we can go back to free access to the clubroom with monthly meetings etc back to normal.

If the restrictions on numbers are lifted but NOT those regarding distancing / masks, then we will continue with the booking system / limit of 5.

On March 29th there is a possible relaxing on local travel restrictions. Therefore, we believe it would be permitted for members to travel to the clubroom (currently either Chris or myself are the only visitors to check the premises). If there is a need, we would allow individual members (or from one household) (essentially keyholders) to use the clubroom. If any of you would like to do this, we will introduce a modified booking system to do this. Email me if you like to do this.

I will convey any changes to clubroom access to members via email.

Obviously, the rules would not have changed in time for our June show. As mentioned in the previous newsletter, we hope to hold a memberís only event instead of the show. We are still intending to do this, but will wait a bit longer to confirm a date etc. Its most likely this will be at the Welcome Hall.

Finally, the Felixstowe Lions are hoping to hold their charity railway event at the Leisure centre on Sunday 17th October. We have been invited to attend and Ďfillí our normal space. We will arrange what we take nearer the time.

PROJECTS (1) by Trevor

TRANSIT CONVERSIONS

As you drive around (on your essential journeys) you wonít go far before you see a panel van or specialist vehicle based on one. Most numerous is the Ford Transit. Ford build these in five different lengths and two heights, plus ladder frame chassis cab versions for coachbuilders to use.

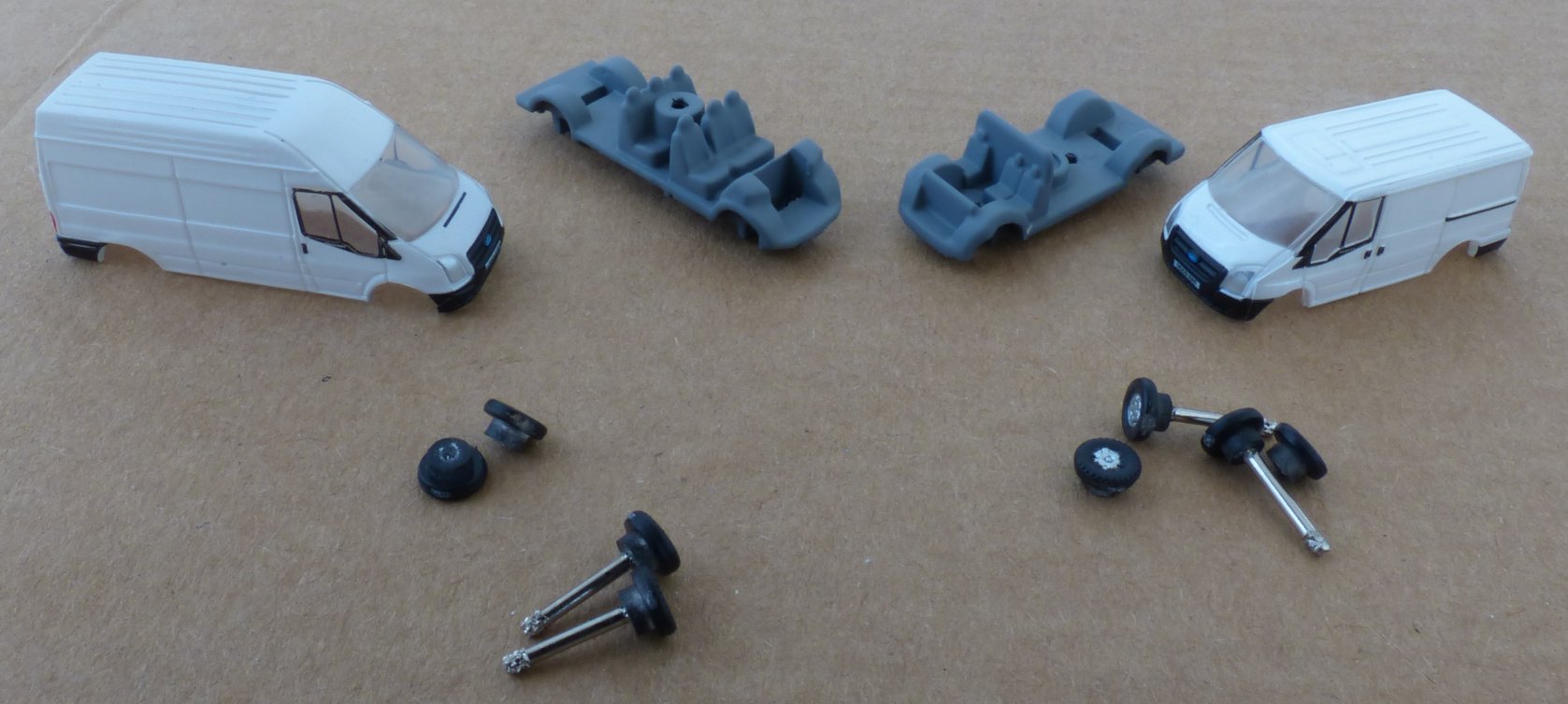

Oxford Diecast currently have two Transit panels vans in their range L1H1 & L4H2, which are available in a number of liveries. I decided Iíd have a go at using these as a basis for some specialist versions. At about £5 for a van not a great loss if it all goes wrong.

The early Oxford models had a diecast chassis and body with a clear plastic insert for the windows. The later models (including the vans) have a diecast chassis and a body moulded in a clear plastic. The body looks to be printed with body colour / detail. This gives a perfect flush glazed finish with no prismatic distortion. It also means they are easier to work with / modify than the metal bodies. These are very nicely detailed models.

So, what to build? In my spares box I already had a box van body off a Base Toys 60ís lorry (which Iíd converted to a cattle wagon). This would make a suitable body for a Transit. Second, a Luton box van is a simple shape to build and I figured a roller back door and tail lift were also fairly easy to model. Finally, a vehicle recovery truck. There are a couple that park near to me and are the fixed body Beavertail type. A little bit more work to model, but not too difficult and I could take a look at one when out for a walk.

Searching the internet there is plenty of information on the Ford and other websites with details of sizes etc of the various conversions. Pictures are also easy to find.

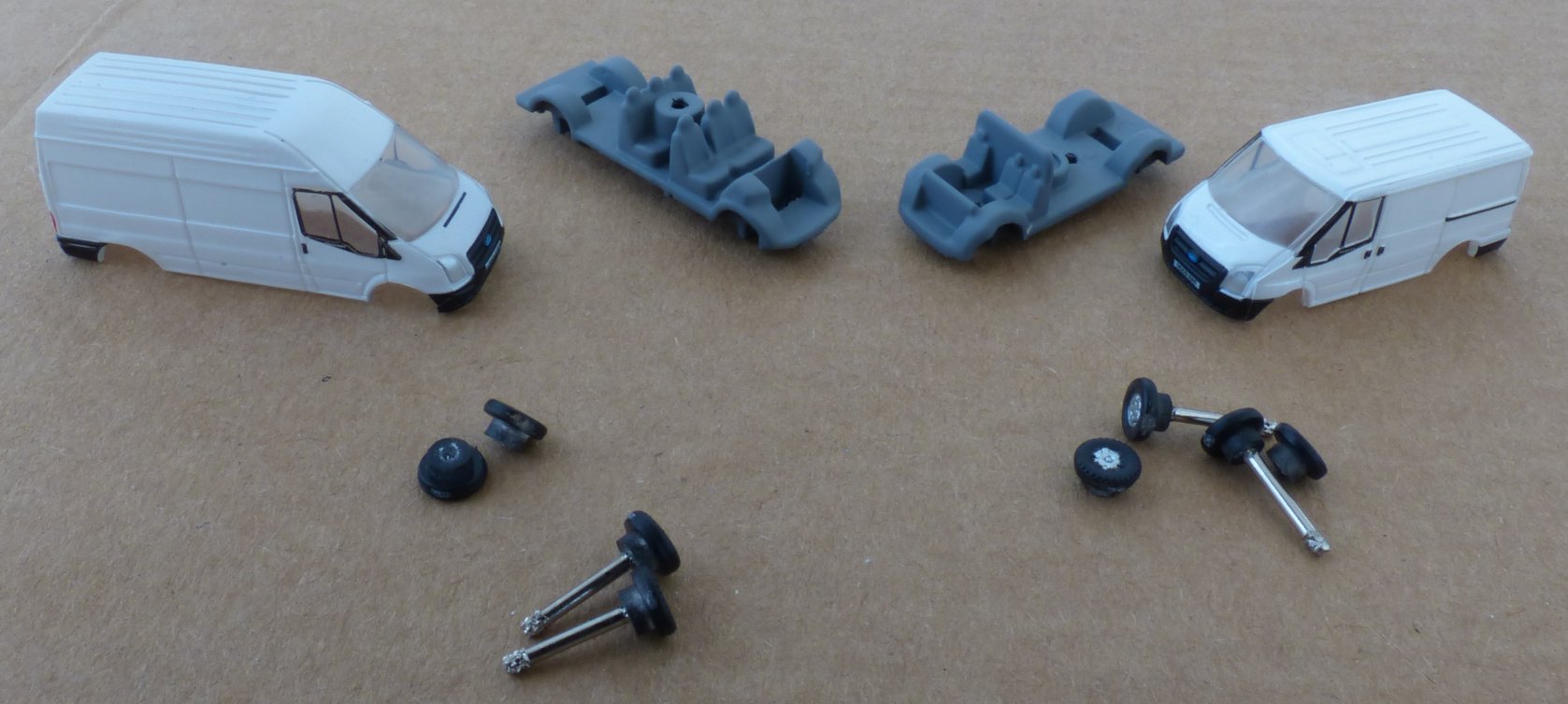

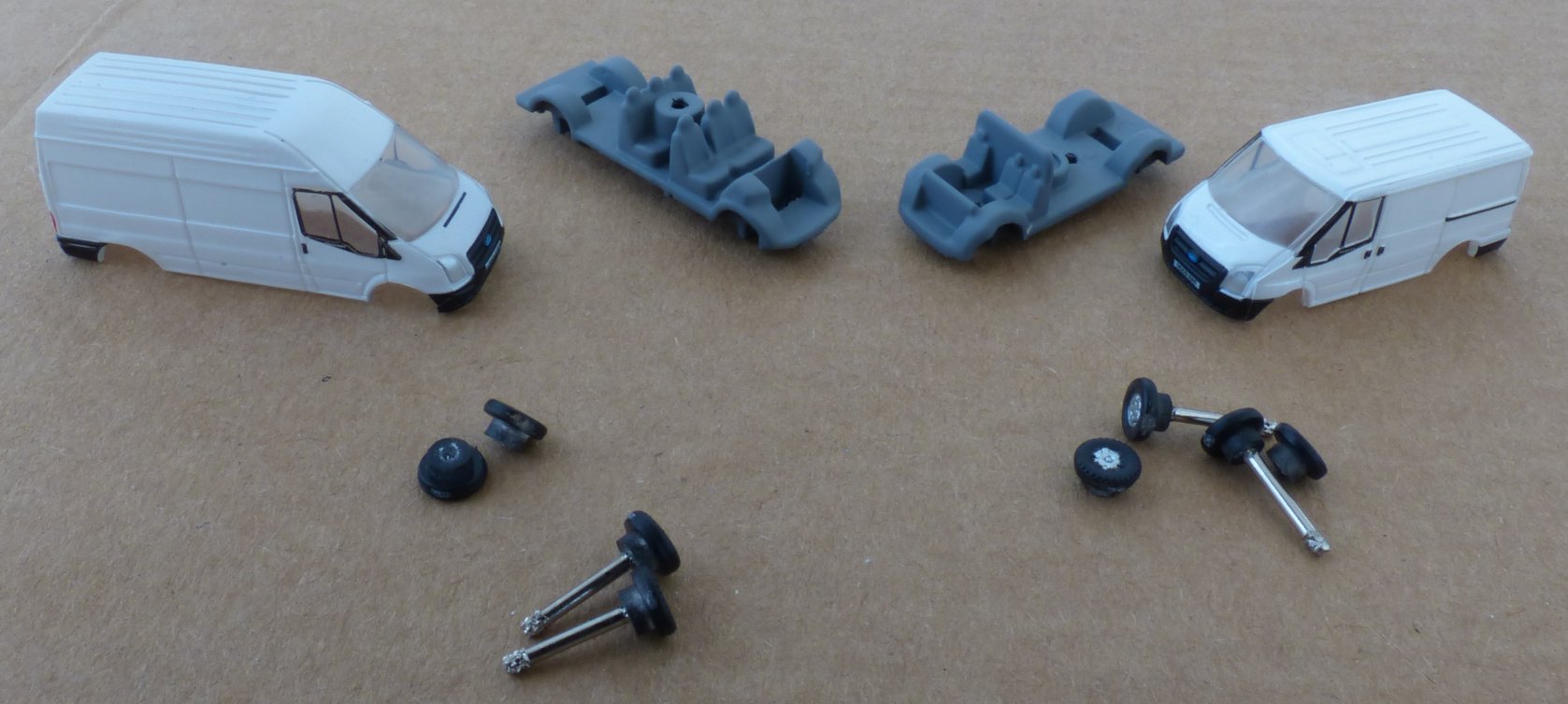

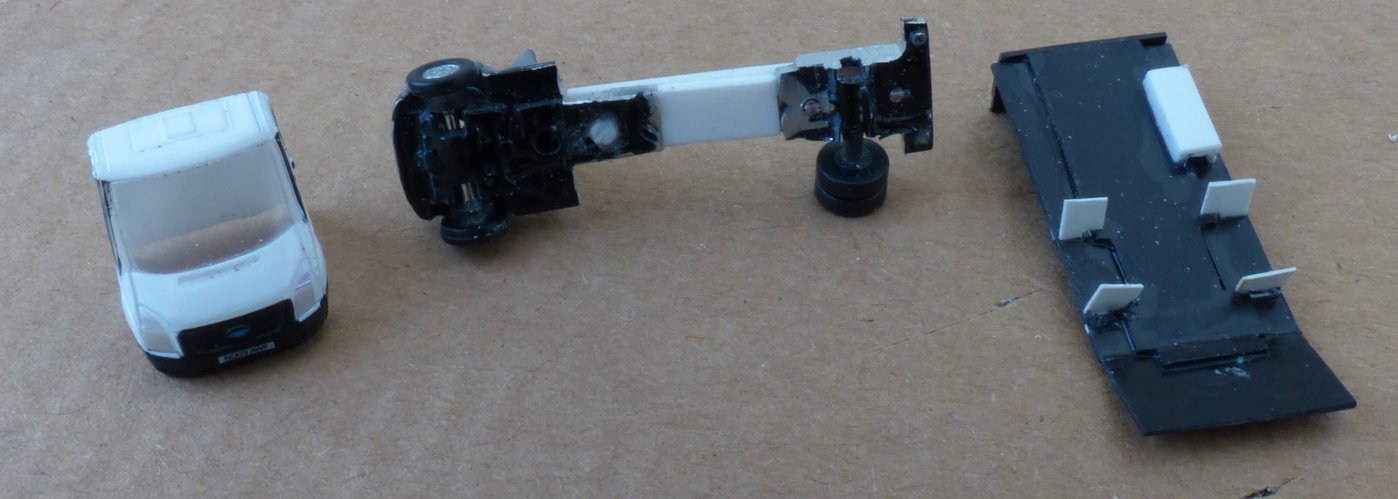

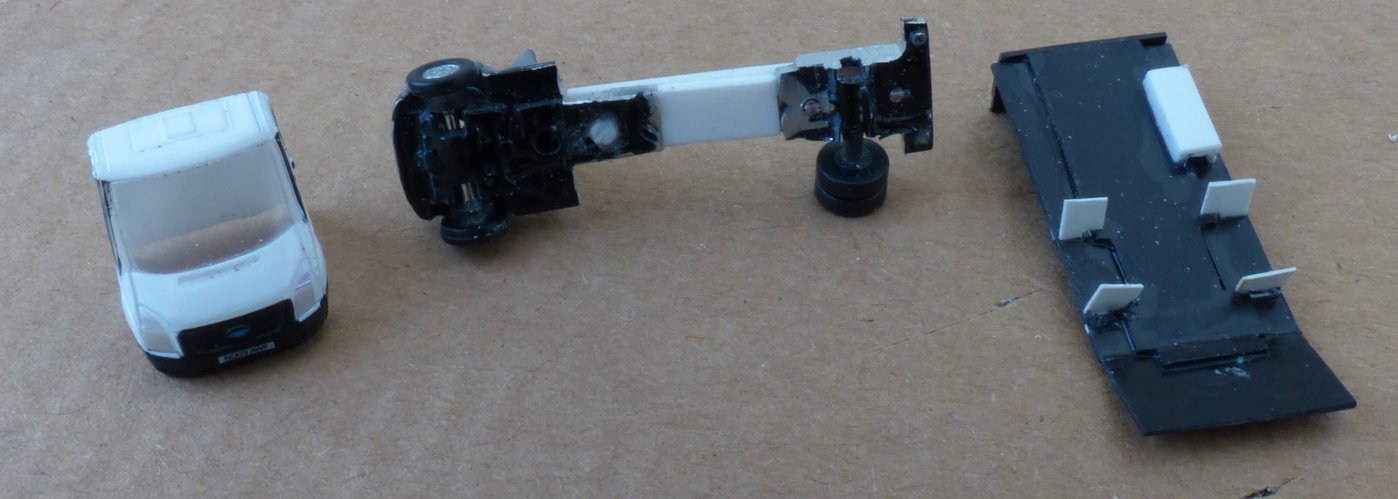

I already had examples of both of the Oxford Transits in white. The low cab version was more suitable for the Beavertail with the higher versions providing an air deflector to the body behind. First stage is to strip down the Oxford models which are held together with a screw. You might need to insert a thin blade at the body / chassis joint to ease them apart.

Iíve sprayed the chassis grey so that you can see the differences in the models. The smaller van has a single row of seats and a bulkhead. The larger van has a second row of seats, although the fixing screw passes through the middle. Not so obvious is the position of the seats relative to the van chassis / body. The smaller van has them closer to the front wheels, whilst on the larger van they are further back. I assume the smaller van is FWD whilst the larger is RWD with more space required for an inline engine / gearbox. The result is that it causes a few problems when modifying the larger van body getting the seats in the correct position. In hindsight Iíd use the smaller van for any future conversions.

As mentioned, I had the following box van body in my spares.

For the smaller box van, I kept the chassis pretty much as supplied. Some filing to allow the body to fit was required. The metal is relatively soft and easy to remove with a needle file.

The Oxford models have sliding side doors and the relief detail for these makes a perfect cutting guide just behind the cab front. Using a fine razor saw I first cut through both sides, which gives guides for then cutting the roof. I used a mitre block to help keep square and true. I then cut a piece of plasticard to form the back of the cab. This is a bit of trial and error as the body sides are curved. This is where the position of the front seats on the larger van causes a problem as although Iíd filed down the back of the seats, I still needed to shape the new cab back to fit over these.

The box body I had was both too long and too high. Again, the razor saw / mitre block was out to cut the front section off the box and remove a section at the bottom (to a moulded line). A piece of plasticard was used to fill in the front of the box. Its slightly wider than the cab, but as it would be tricky to narrow it, I decided to leave it.

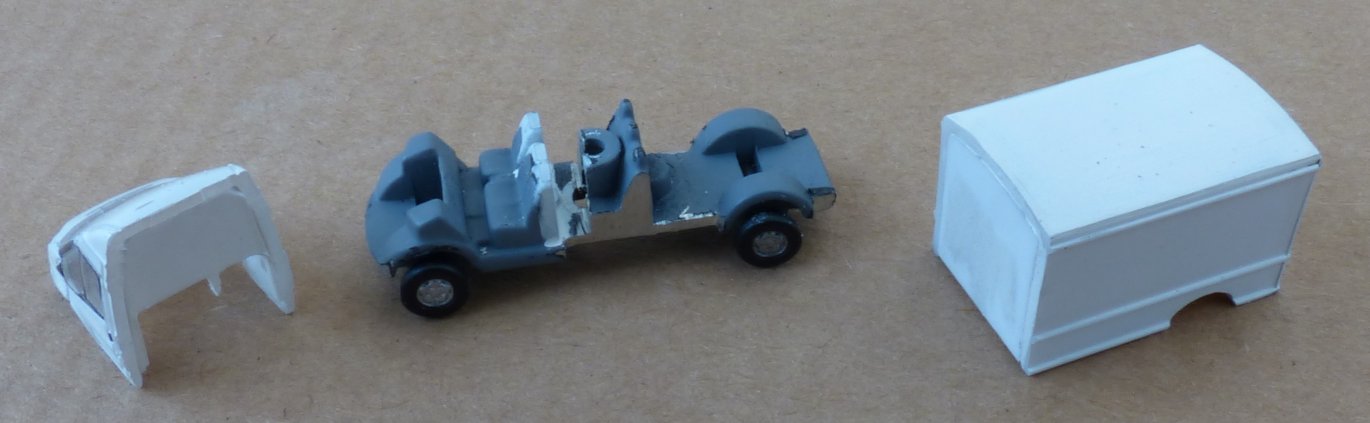

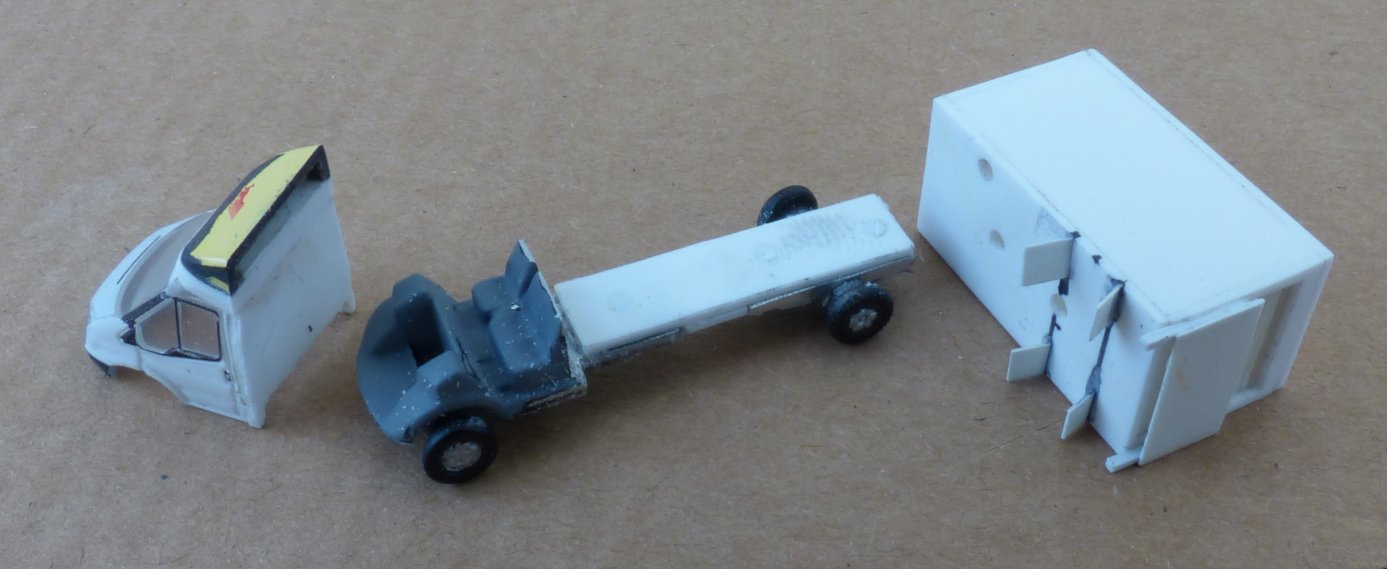

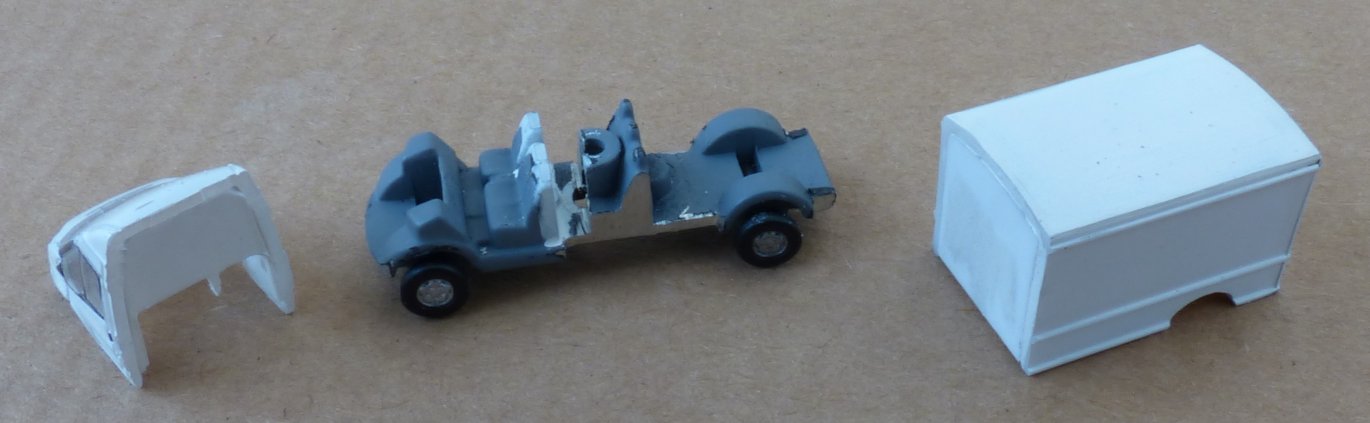

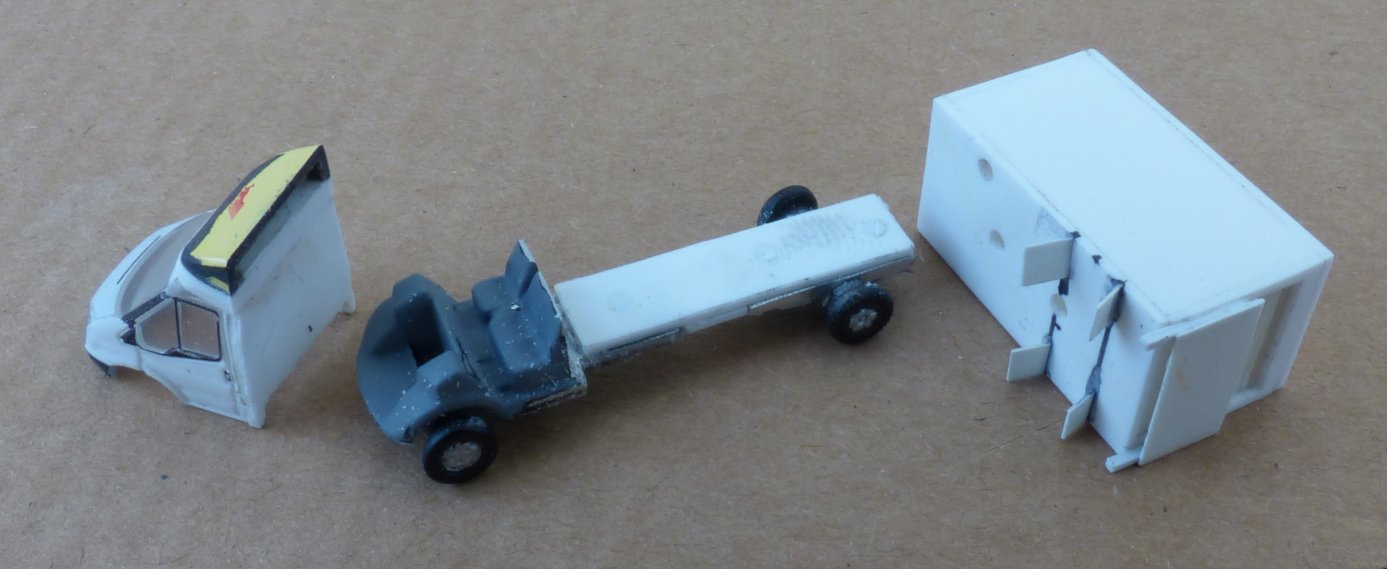

The set of modified parts are shown below.

Before final assembly the body parts were sprayed with rattle cans (Halfords work particularly well). I used masking fluid to protect the cabs windows. Again, in hindsight it would be better not to have to spray the cab as the resulting finish is not as good as the original. Iíd scratched my cab during modification so had to paint it. Detailing was hand painted.

The Luton version required more work including chassis lengthening and a scratchbuilt body. For the chassis I filed off the second row seats and narrowed the chassis sides to produce a more typical ladder chassis size. I then cut the chassis in half and used plasticard to extend this to the wheelbase of the largest version Ford manufacture. You see versions of this type with both single and double wheels at the rear. I chose to use the single wheels from the Oxford model.

The Luton body is a simple rectangular box made from plasticard. Remember to drill a vent hole for glue fumes to escape. For the roller door I used some plank scribed Evergreen sheet. The tail lift is a couple of pieces of square section for the runners and flat sheet for the deck. Small pieces are attached to represent mud guards.

The cab was cut down as previously described. This time a piece of plasticard was fitted across the back of the cab allowing it to fit behind the seats without modification. The air deflector on the cab was not high enough, so was cut off and a new larger one fabricated from scrap parts.

The parts for this are shown below.

As per the smaller van it was finished by spray / hand painting.

Finally, onto the beavertail. Again, this required work to lengthen the chassis and a scratchbuilt body. As per the Luton version the chassis was narrowed by filing, then cut in half / lengthened with plasticard. From my spares box I found a double wheel rear axle. Beavertails with single wheels are restricted on the size of vehicles they can carry (e.g. not heavy 4x4s).

There are many variations on the bodies fitted. The simplest is essentially a flat sheet, but one of my local ones has raised areas where wheels go and a shallow well in the middle. I chose to build this latter type and, essentially, itís built from three plasticard strips. I then attached a full width sloping section at the rear. From pieces of scrap plastic card, I made a representation of the winch fitted to these vehicles and a storage box under one side. I also made a pair of detachable ramps for loading vehicles.

As I was using the smaller Oxford van, I could simply cut off the cab and fill in the back and it would fit on the chassis over the seats without additional modification. I chose to have a solid back as easier to model, but many have a rear window. I filed a piece of square section plasticard to a more rounded profile to make a hazard light bar for the cab roof. I also made a representation of a floodlight for the rear of the cab roof.

The parts are shown below.

This time a decided to spray the cab / body in red. The bed is normally made in aluminium, so this was suitably painted. After painting I added a representation of the tie straps used to secure vehicles using plastic insulation from some very fine wire.

So how did they turn out?

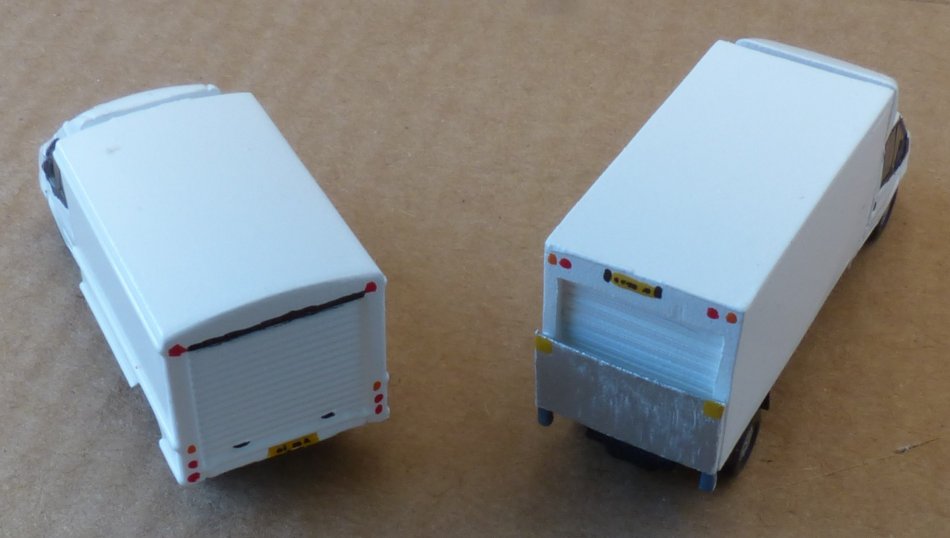

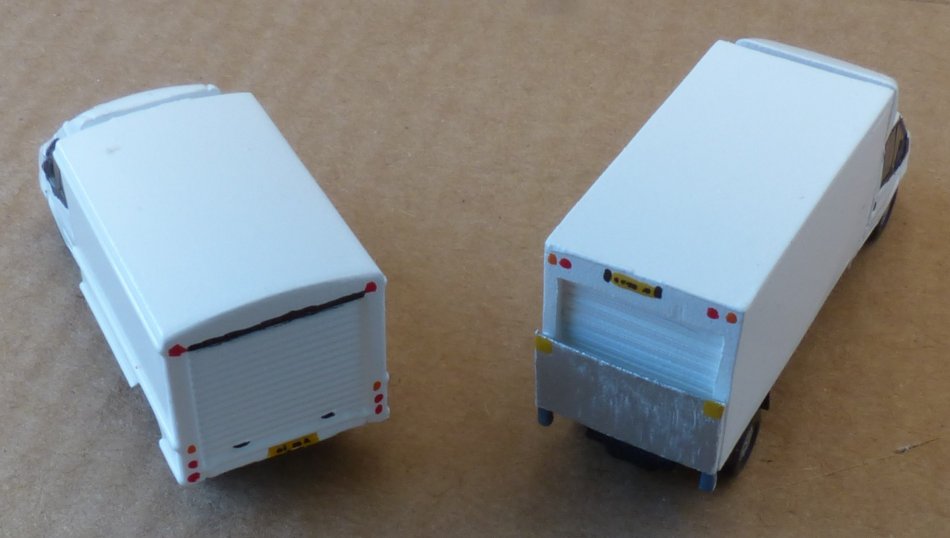

First some front / rear images of the box vans. Both have an added driver and the smaller van has had the driverís window cut out, so it appears open.

Some time ago I modified the large Oxford van to add a cherry picker arm. This was a scratch-built arm / bucket. Other than drilling some holes in the van body to fit the parts it had no other modifications. Iíve included it alongside the completed beavertail in the following images.

So how do I think these have turned out, what have I learnt, and would I do anymore?

Well, Iím quite pleased with them. As with most small models you donít notice blemishes until you take some images and I can see a couple of bits I could have finished a bit better. However, when looking at them myself and from a more normal viewing distance Iím happy.

Unless you are going to build something based on the larger van (like the cherry picker), then using the smaller van if you are cutting the cab off is a better option.

Avoid having to paint the cab if you can. If you do choose to paint it then spraying with an airbrush might be a better option as it will give a finer finish than the rattle can route, although an airbrush is a lot of effort to go to for one small model.

I may well make some other variants. When making these I did consider a tipper truck version, like you see many small builders using. Iíve also recently seen a couple of small horse boxes build on the Transit chassis.

Now Iíve made these it should guarantee Oxford will soon be adding some of these variants to their range.

Finally, before you ask, Iím not taking any commissions.

NEW TOYS

New models recently purchased by members:

5 GraFar Presflo 20t bulk powder wagons in ĎBulk Tunnel Cementí livery.

A Dapol Chiltonian Biscuits gunpowder wagon.

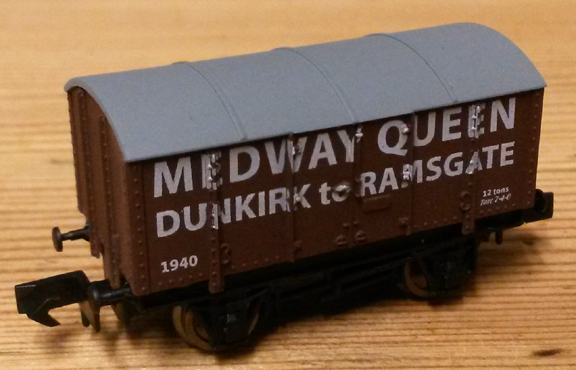

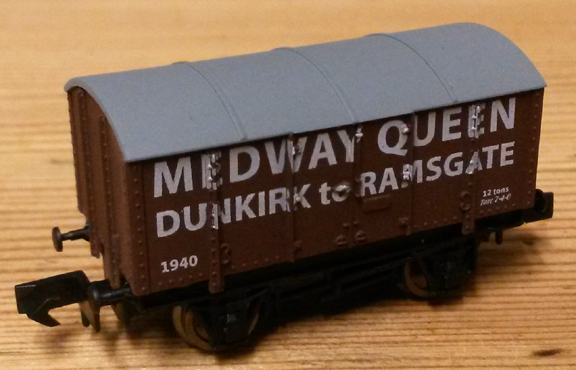

A Dapol Medway Queen gunpowder wagon in the brown livery.

A Dapol Medway Queen gunpowder wagon in the grey livery.

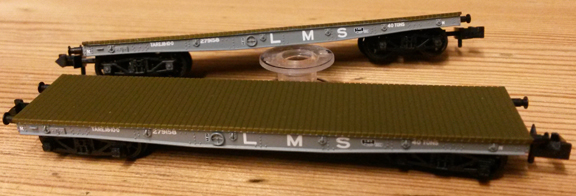

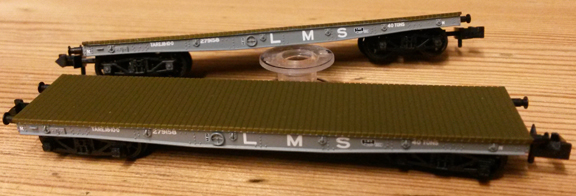

2 GraFar LMS 'Parrot' flatbed wagons.

PROJECTS (2) by Mike

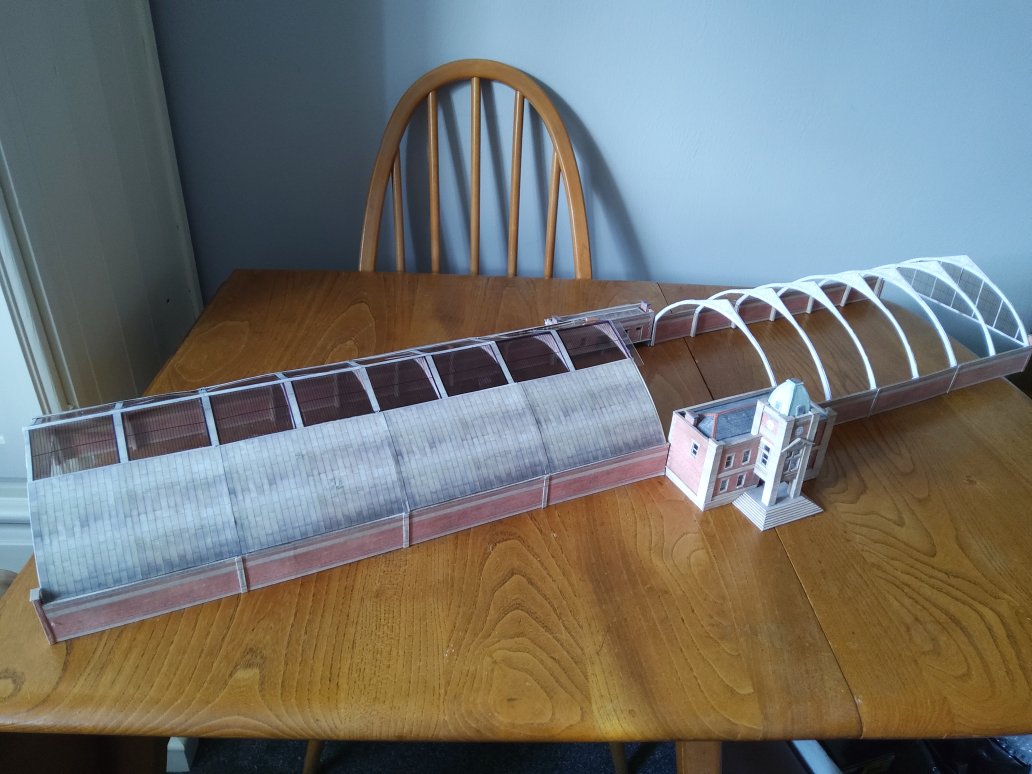

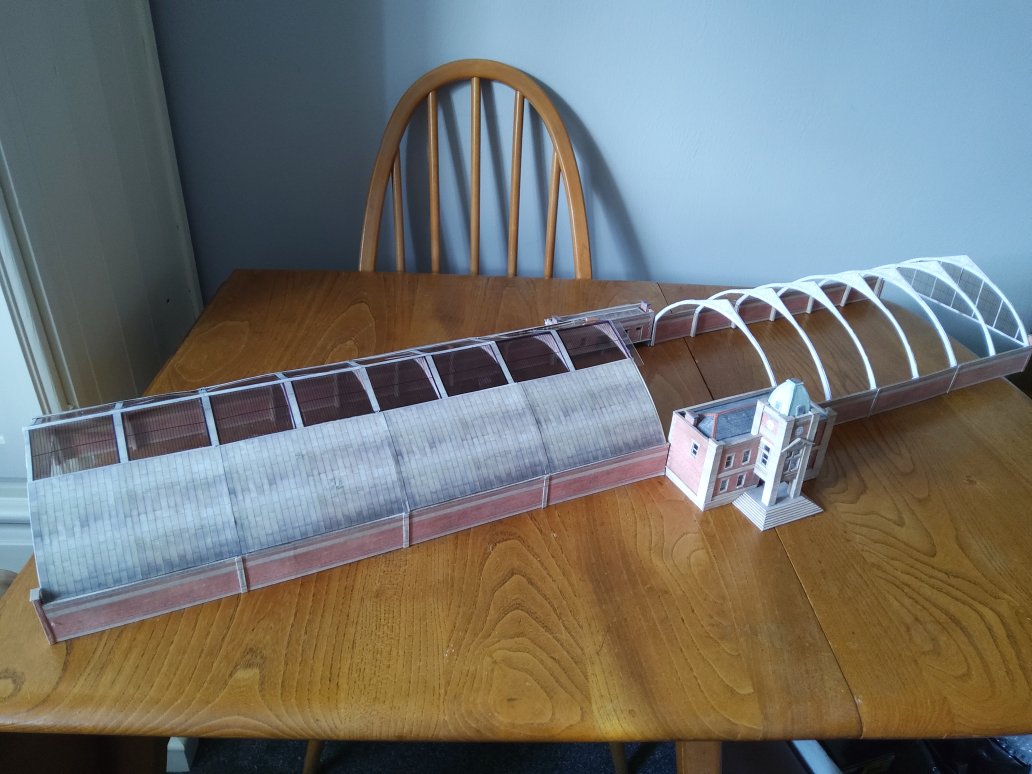

I have found it very difficult to motivate myself to get on with anything lately, but I did have a little push to do some more on my giant mainline through station. It really is big, about three and a half feet long, a job to get into a photo!